Our company is a professional commercial chocolate making equipment suppliers in China. The series of commercial chocolate making machine is the most advanced machine in our company, which is technical machine to make chocolate. The whole production line mainly includes chocolate fat melting machine,sugar grinding machine, chocolate conche machine, chocolate storage tank, chocolate temperature machine, chocolate moulding machine and chocolate delivery pump.

The machines in the CHICOLATE MAKING MACHINE:

1.Chocolate Fat Melting Machine

The cocoa butter and cocoa liquor blocks are solid at normal temperature. The main function of the chocolate fat melting machine is to melt the solid block into cocoa butter. It adopts electric heating, automatic temperature control, and can also be melted by steam heating. The melting process is required before the chocolate material is put into the refiner. In addition, the cocoa butter melting tank extends the life of the refiner/refiner.Our chocolate fat melting machine is a water jacket, and the jacket pot is ss304.

2.Sugar Grinding Machine

The machine is suitable for grinding of medium and low hardness materials, and the fineness is adjusted between 30 and 150 mesh. It has the advantages of high yield, fine particle size, low noise, low energy consumption, simple maintenance and convenient installation.

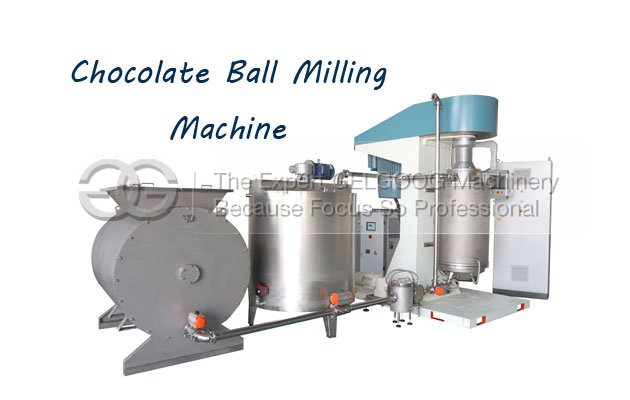

3.Chocolate Ball Milling Machine

The inner cylinder of the ball mill is made of abrasive steel and subjected to special heat treatment. Ensure that the inner cylinder is not deformed, at the same time the best wear - resistant degree, and can ensure that the chocolate paste iron content will not exceed the standard. This ball mill USES food grade Belgian original package imported steel ball, at the same time, also guarantees the steel ball wear resistance. The mechanical seal imported from Germany has been used to completely solve the problem of easy leakage of materials in the working state of grinding cavity. The machine is also equipped with the automatic control system for the circulation of hot and cold water, and is more suitable for the production of chocolate size, toothpaste, cosmetics and other sizing requirements of food fineness process.

4.Chocolate Storage Tank

The chocolate storage tank is an important equipment in chocolate production. It is mainly used for heat preservation and storage of chocolate syrup after fine grinding, to meet the technological requirements of chocolate production and adapt to the requirements of continuous production. In addition to the functions of melting, cooling, heating and insulation, the product can be continuously stirred to the chocolate paste, and also has the functions of degassing, deodorizing, dehydration and preventing the separation of the paste grease.

5.Chocolate Temperature Machine

The temperature machine plays an important role in the production process of chocolate. It can strictly control the temperature required in each stage of the tempering process to ensure the demoulding and product quality of chocolate. The machine adopts vertical structure. The chocolate size is input by the slurry pump from the bottom of the tempering machine, and the chocolate size can achieve five levels of continuous tempering through four tempering regions and insulating regions, so that the temperature curve of the chocolate size can meet the technological requirements, and the chocolate products can be guaranteed with excellent crystallization, good taste, smoothness and good preservation performance.

6.Chocolate Moulding Machine

This chocolate moulding machine is a special advanced equipment developed by our company for chocolate pouring molding. It integrates machine, electricity and gas control. The whole production process includes automatic working procedures of baking mold, pouring, oscillation, cooling, demoulding and conveying. This machine has the advantages of high yield, flexibility, high demoulding rate and many varieties of chocolate. It can produce pure chocolate, sandwich and double color chocolate, granule mixed and poured chocolate. It can produce pure chocolate, sandwich and double color chocolate, granule mixed and poured chocolate.

7.Chocolate Cooling Tunnel

The chocolate cooling tunnel is mainly used for cooling molding of chocolate products after pouring. The whole machine is stable in quality, energy saving, operable and convenient in maintenance.The length and width of the cooling tunnel can be customized according to the customer's requirements.

8.Chocolate Delivery Pump

The equipment is a machine for transporting chocolate, and the heat preservation function is realized in the conveying process. The machine has a compact and reasonable structure, stable and reliable operation, and low maintenance rate.

Our service for Commercial Chocolate Making Machine:

1.One-year warranty for defects caused by machine quality. The customer is responsible for the fault caused by wrong operation, human problem, etc. We will help solve the problem by mail or professional guidance from video. And as supplier, we can supply all kinds of parts of the machine.

2.Engineer can be sent to the oversea to provide installation and training guide.

We are famous commercial chocolate making equipment supplier. And we can supply the machine with the most favorable price and best quality. If you have demand for the chocolate making machine, you can contact us!

|

Chocolate Melting Machine |

|

|

Model |

TRYG240 |

|

Material |

Stainless Steel |

|

Capacity |

240L |

|

Pump power |

0.2KW |

|

Electric heating power |

6KW |

|

Net weight |

180kg |

|

Dimension |

1600×800×900mm |

|

Sugar Grinding Machine |

|

|

Model |

TFTJ250 |

|

Capacity |

250kg/h |

|

Total Power |

9KW |

|

Dimension |

1100×750×1800mm |

|

Net weight |

420kg |

|

Feeding Granularity Size |

0.5-2mm |

|

Average Grain |

150-180µm |

|

Rotation Rate |

3800r/min |

|

Chocolate Conche Machine |

|

|

Model |

TJMJ500 |

|

Capacity |

500L |

|

Main motor power |

11KW |

|

Regulating motor power |

1.5KW |

|

Electric heating power |

6KW |

|

Dimension |

2000×1860×1250mm |

|

Net weight |

2800kg |

|

Fine Grinding Granularity |

20-25µm |

|

Chocolate Storage Tank |

|

|

Model |

TBWG500 |

|

Material |

Stainless Steel |

|

Capacity |

500L |

|

Main motor power |

1.5KW |

|

Electric heating power |

4KW |

|

Dimension |

Φ1000×1380mm |

|

Net weight |

600kg |

|

Chocolate Moulding Machine |

|

|

Model |

TQJJ150 |

|

Capacity |

100-200kg/h |

|

Power |

7.47KW |

|

Quantity of mould |

275×175×30mm |

|

Net weight |

500kg |

|

Dimension |

4300×520×1500mm |

|

Chocolate Cooling Tunnel |

|

|

Model |

TLSD400 |

|

Material |

Stainless Steel |

|

Temperature of cooling tunnel |

5-10℃ |

|

Main motor |

1.5KW |

|

Net weight |

2500kg |

|

Dimension |

5400×1230×1930mm |

|

Cooling compressor |

5HP |

|

Chocolate Pump |

|

|

Model |

SJB-32 |

|

Material |

Stainless Steel |

|

Flow Rate |

32L/min |

|

Power |

1.5KW |

|

Dimension |

780×390×350mm |

|

Net weight |

120kg |

|

Chocolate Pump(speed adjustable) |

|

|

Model |

SJB-25 |

|

Material |

Stainless Steel |

|

Flow Rate |

25L/min |

|

Power |

0.75KW |

|

Dimension |

700×300×350mm |

|

Net weight |

105kg |

E_mail

E_mail contact

contact Whatsapp

Whatsapp TOP

TOP