Features

Introduction:

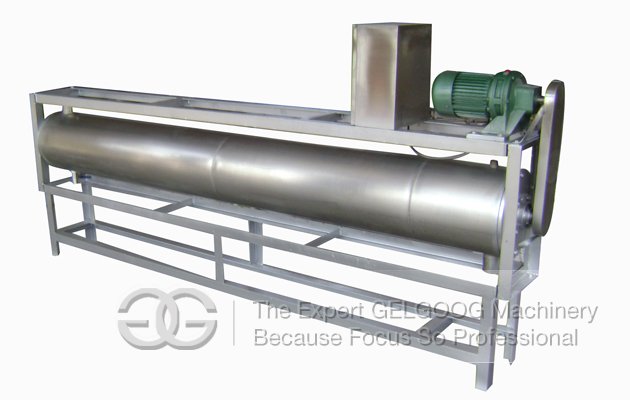

This machine uses heat exchange principle(water cooling) to cool low viscosity to medium viscosity products, such as peanut butter cooler, jam, honey, oil, soup, sauces, fruit purees and juice, baby food etc. Our machine is made of stainless steel, high quality, conform food hygiene and safety requirements. For cooling peanut butter, it is usually connect with peanut butter grinder or peanut butter degassing tank, peanut butter after grinder or degassing tank is a little high temperature, through cooling machine, down its temperature soon, then can go to next process step, like filling peanut butter. For peanut butter cooling effect is related with cooling machine length. Same capacity machine, length longer, cooling effect better. No need air pump, water source pass machine by circulating water of water pool or nature water from pipes. When using machine, in order to keep its cooling effect, pay attention to water temperature and cycles. If water temperature is too high, think method to down its temperature or change water.

This machine uses heat exchange principle(water cooling) to cool low viscosity to medium viscosity products, such as peanut butter cooler, jam, honey, oil, soup, sauces, fruit purees and juice, baby food etc. Our machine is made of stainless steel, high quality, conform food hygiene and safety requirements. For cooling peanut butter, it is usually connect with peanut butter grinder or peanut butter degassing tank, peanut butter after grinder or degassing tank is a little high temperature, through cooling machine, down its temperature soon, then can go to next process step, like filling peanut butter. For peanut butter cooling effect is related with cooling machine length. Same capacity machine, length longer, cooling effect better. No need air pump, water source pass machine by circulating water of water pool or nature water from pipes. When using machine, in order to keep its cooling effect, pay attention to water temperature and cycles. If water temperature is too high, think method to down its temperature or change water.

Advantages:

1.Stainless steel material, ensure machine quality and use life, and meet food cooling demand.

2.Use water cooling principles, cooling effect is better, no waste of water, save cost and no environment pollution.

3.Easy to use. Just connect this machine with processing material and water, it will cool it automatically. If use in automatic line, just connect before and after machines, which will work automatically, no need person to operate. Save labor.

4.Beautiful and elegant performance.

5.Easy to clean. After using machine, just pass water, can clean machine well.

6.Environment Friendly. Use water cooling only, no need other fuel or power to supply refrigeration, and water is cycle, no waste.

7.Multifunctional usage, can cool various liquid and paste. Is good choice for many industrial.

Technical Data

| Model | GG-2000C |

| capacity | 300-500kg/h |

| dimension | (2000~3000)*400*1700mm |

| weight | 400-600KG |

| Package dimension | (2100-3100)*500*1800mm |

| power | 0.75kw |

| voltage | 380V/50HZ |

FAQ

Q:What’s the Packing and Delivery ?

A: We adopt the export standard wooden packing . And we can deliever through sea , DHL , Train transportation

Q. when the product will be deliver ,plz?

A.Generally ,we will delivery commodity within 7 days,except custom-made.

Q:What if customers know little about import processing?

A: Our factory has rich experience in export.We will assist customers with needs step by step, from placing orders to receiving poutry feed manufacturing equipment.

Q: What's the material of the machine?

It is made of stainless steel

Q: Do you supply samples ?

A: We are factory, and making machines costs, Large order , Large discount , we can not offer sample machines .

Related Products

E_mail

E_mail contact

contact Whatsapp

Whatsapp TOP

TOP