Features

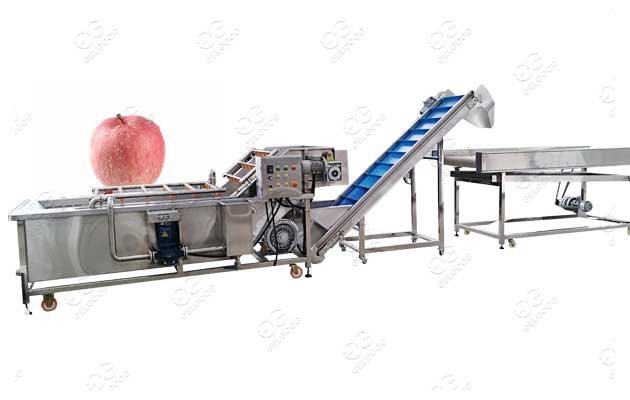

Our apple washing machine adopts high-pressure water flow and bubble generating device. The apple washing machine price simulates the manual hand rubbing cleaning method to clean the stains on the fruit skin very cleanly, and the effect of the brush roller cleaning machine is more significant.

The apple washing machine for sale are made of food-grade stainless steel, which is durable and well protected.

Bubble type apple fruit washing machine working principle:

The energy generated by the bursting of bubbles coming out of the high-pressure device when they come in contact with apples and peaches. This energy will have an impact and scrubbing effect on the surface of the apple and peach. Therefore, this bubble apple washing machine can scrub the surface of fruits, remove pesticides on the surface of fruits, and clean the fruits. At the same time, an appropriate amount of chemical water can be added for disinfection and fixation. Floating matter can overflow from the chute, and the sediment is discharged from the sewage outlet to achieve the purpose of cleaning. Our fruit apple washing machine is divided into large, medium and small equipment specifications can be customized according to your requirements

Features of Apple Peach washing equipment

- Automatic continuous cleaning

- Cleanliness is high. The washing machine equipment has a fast cleaning speed, and the cleaning is very clean and there is no residue. The cleaned apples and peaches are more than three times more than manual conventional washing methods

- The conveying part of the washing machine adopts SUS30. Stainless steel mesh belt, stable operation and long service life

- Simple operation and convenient maintenance

The advantage of the bubble washing machine for fruits and vegetables is that the equipment can be operated on an assembly line. It can be used for cleaning fruits and vegetables such as cabbage, shallots, leeks, spinach, beans, strawberries, blueberries, mushrooms, fungus, green peppers, kelp, sea cucumbers, etc. It is suitable for cleaning equipment for vegetable distribution, deep processing of vegetables, and quick-frozen vegetable manufacturers.

Technical Data

| Model | Power(KW) | Size(mm) | Capacity(KG/H) | Weight(KG) | Roller Size(mm) |

| GGXM800 | 1.1 | 1600*850*800 | 400 | 220 | 800 |

| GGXM1000 | 1.5 | 1800*850*800 | 600 | 260 | 1000 |

| GGXM1200 | 1.5 | 2000*850*800 | 800 | 280 | 1200 |

| GGXM1500 | 2.2 | 2300*850*800 | 1000 | 320 | 1500 |

| GGXM2000 | 3 | 2800*850*800 | 1500 | 420 | 2000 |

| GGXM2600 | 4.37 | 3100*850*1450 | 2000 | 600 | 2600 |

FAQ

Q:which country have you ever been exported?

A: New Zealand, Azerbaijan, kyrgyzstan, Uzbekistan, Brazil, etc..

Q:What are the payment methods?

A:Western union,T/T,LC are accepted.

Q:What if customers know little about import processing?

A: Our factory has rich experience in export.We will assist customers with needs step by step, from placing orders to receiving poutry feed manufacturing equipment.

Q:What’s the Packing and Delivery ?

A: We adopt the export standard wooden packing . And we can deliever through sea, Train transportation

Related Products

E_mail

E_mail contact

contact Whatsapp

Whatsapp TOP

TOP