Features

With the acceleration of the pace of modern life, people not only want to eat well, but also want to save time. In this case, the market for clean vegetable processing machine has emerged. Clean vegetables are products that sorting, washing , cutting, drying, package and keep vegetables fresh.

What is clean vegetable processing:

Clean vegetables refer to products that have undergone a series of treatments such as grading, washing, cutting, preservation, and packaging to keep fresh vegetables in a fresh state. Consumers can cook and eat directly after purchase without further processing. It can meet the hygiene requirements of direct cooking and raw food, and has the characteristics of freshness, convenience, hygiene and nutrition.

High-quality clean vegetables have become the mainstream of vegetable consumption in developed countries such as Europe, America and Japan. Clean vegetable processing changes to a certain extent the traditional supply mode of vegetables directly entering the circulation field after harvest, and realizes the modern circulation mode of centralized processing and decentralized supply of vegetables in the production area. This is one of the development directions of vegetable processing.

What Are The Options For The Clean Vegetable Processing Production Line?

The configuration requirements of the small clean vegetable processing line.The overall configuration of the clean vegetable processing line is based on its technological process. The technological process is: grade selection→cleaning→organization→cutting→preservation→dehydration→sterilization→packaging→refrigeration.

According to the fruit and vegetable processing technology, the clean vegetable processing line can be divided into: graded selection part→cleaning part, sorting and cutting part, fresh-keeping part, dehydration and sterilization part, and packaging and refrigeration part.

The processing flow of clean vegetable processing steps:

(1) Classification selection part:

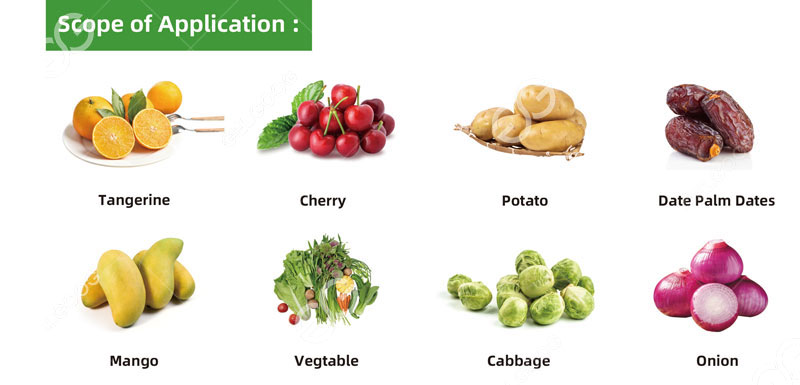

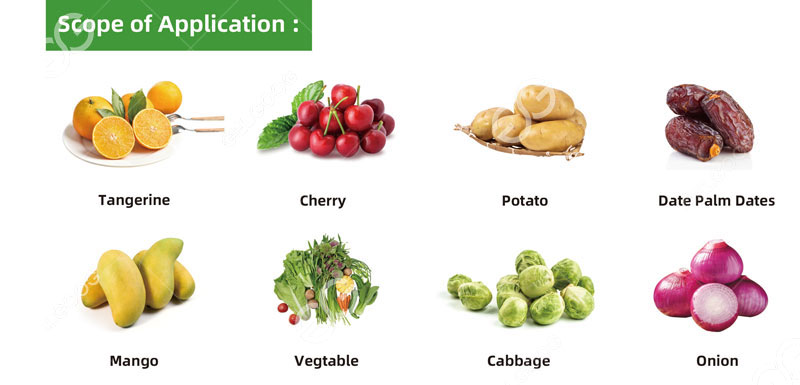

Our fruit and vegetable sorting machine of vegetable processing machine will classify fruits and vegetables. It can be classified by size or by weight.

(2) Cleaning part:

In the vegetable processing steps, washing is an important process to extend the preservation time of vegetables. The cleaning process can be cleaned with a air bubble vegetable cleaning machine first, and then sprayed with clean water.

(3) Cutting part:

The size of clean vegetable cuts is one of the important factors affecting product quality. Use a sharp knife to cut vegetables for a long time. Therefore, it is necessary to reduce the number of cutting as much as possible. So the vegetable cutting machine cutting knife is made of stainless steel, and the blade is thin and the blade is sharp, which can effectively extend the storage time of vegetables.

(4) Fresh-keeping part:

Clean vegetables are more prone to spoilage than unprocessed vegetables. The fresh-keeping agent has a certain effect on the fresh-keeping of clean vegetables, and the higher the concentration, the longer the soaking time, the better the fresh-keeping effect. We provide a complete solution for clean vegetable processing, and we help customers consider every step.

(5) Dehydration part:

After the cut vegetables are kept fresh, there is a lot of moisture on the surface of the vegetables, and air-drying equipment is required for proper processing to remove the moisture in vegetable processing machine steps. We provide two types of air drying equipment for customers to choose from, which are suitable for different types of fruits and vegetables.

(6) Sterilization part:

Clean dishes generally choose ultraviolet sterilizer for sterilization in vegetable processing machinery. It should be noted that the sterilization time should be set to an appropriate time.

(7) Packaging part:

Appropriate vegetable packaging machine and packaging materials can extend the shelf display time of clean dishes. Help customers reduce unnecessary waste.

(8) Cold storage part:

To maintain the quality of clean vegetables, it is important to keep them at low temperature. We have different types of refrigerated cabinets, which can be provided according to the specific needs of customers. The commonly used refrigeration temperature is 4℃-8℃, which can avoid the phenomenon of chilling damage.

Fruit And Vegetable Processing Machinery Manufacturers:

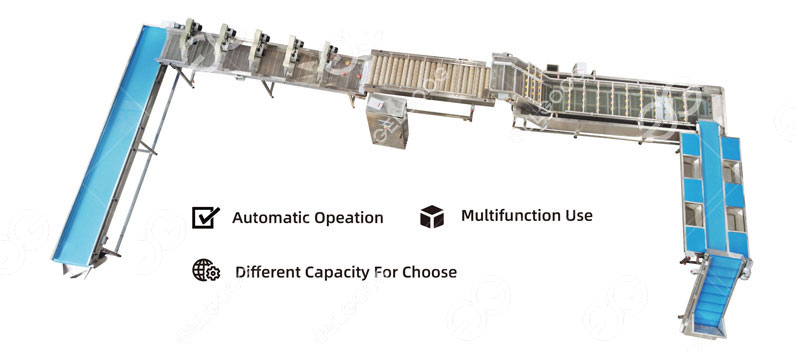

We specialize in the research of food processing equipment. The clean vegetable processing line is a complete set of solution newly designed and manufactured by our company after years of practice and combining many successful domestic clean vegetable processing examples.

Our clean vegetable processing line has the characteristics of scientific design process, mature equipment manufacturing technology and high degree of automation. In addition, our clean vegetable processing line can design different washing solution according to different production materials.

The vegetable processing machine suitable for all kinds of factories, school canteens, central kitchens, breakfast projects, etc. At the same time, our factory can provide vegetable processing plant layout, tailor-made, installation and commissioning services according to the customer's production scale and process requirements, in one step, so that customers have no worries.

Global Fruit And Vegetable Processing Market:

During the forecast period (2018-2023), the global fruit and vegetable processing market is expected to grow at a compound annual growth rate of 8.3%. In terms of market share, processed fruits account for 65% of the fruit and vegetable processing industry.

The processed fruit and vegetable sector includes frozen, canned vegetable and fruit, dried fruit and vegetables. Since imports account for a large proportion, accounting for an average of 35%, the income of processors and producers in the processed food sector is strongly affected by international trade.

The increasing understanding of the benefits of fruits and vegetables, the increasing demand for convenience foods, the development of the food service industry, and the increase of modern retail stores have promoted the growth of the fruit and vegetable processing market. The sooner the clean vegetable processing market enters, the sooner it can gain benefits.

Global Fruit And Vegetable Processing Market Scope And Market Size:

The fruit and vegetable processing market is segmented according to type, business type, material and product type.

The fruit and vegetable processing market can be subdivided into pretreatment, peeling/slicing, cleaning, packaging and processing, and seasoning systems.

According to the type of operation, the fruit and vegetable processing market is divided into automatic and semi-automatic. Our company will meet these two models according to the needs of customers.

According to the materials, the fruit and vegetable processing market is divided into fruits and vegetables.

Technical Data

FAQ

E_mail

E_mail contact

contact Whatsapp

Whatsapp TOP

TOP